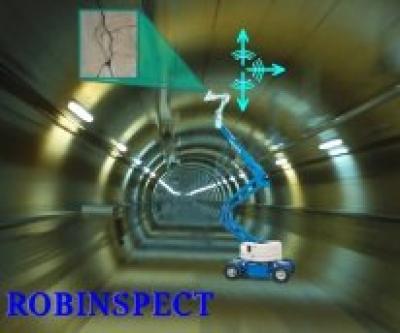

Currently, maintenance and safety inspection of tunnels used for vehicular traffic is carried out by direct in situ observation. This process, which is slow and requires intensive labor, requires that traffic be stopped on entire streets or sections of the underground passageways, resulting in an inconvenience for users. "The automated ROBINSPECT system allows tunnel inspection to be carried out automatically without stopping traffic," highlights the head of the project at UC3M, Carlos Balaguer, a tenured professor in the department of Systems Engineering and Automation. In addition to these advantages, the quality of the inspection is greater, given that it is done by a high-precision multisensory system that can detect tiny fissures and deformities in the structure that are not visible to the naked eye.

The system is basically made up of three components: a vehicle, a small crane and a robotic arm. The vehicle will be similar to an automobile, but smaller and more robust, like a tractor, so that it can move along the irregular surface of the tunnels, the researchers point out. The crane will allow inspection to be carried out from a distance of approximately five meters and will hold the weight of the system's key element: the robotic arm. "This will be equipped with an extensive sensorial system (vision, ultrasound and tactile) and will provide the precision and intelligent movement that will be needed in order to carry out inspections in tunnels," explains another of the engineers who is working on this project, Juan G. Víctores, of UC3M's Robotics Lab, which is in charge of the intelligent control of the robotics components of the system.

A prototype in 2014

The complete prototype of this high-tech robotic crane will be ready for preliminary testing at the end of 2014. These tests will be carried out in three venues: the London underground, three subterranean sections of the Greek Egnatia highway and some experimental tunnels of the VSH in Switzerland. "The final demonstrators of the project will be mostly highway tunnels, which would make the tunnels of the M-30 in Madrid a good place to do the final testing of the system," comments Juan G. Víctores, adding that the device will also be able to detect defects in subway tunnels.

The key to the project lies in combining and integrating different advances and results of recent research in the areas of intelligent robot control, sensor technology and artificial vision with learning. The result will be an autonomous device that will be capable of watching over these civil infrastructures in order to automatically analyze possible defects in the surface, measure the radial deformities of the transversal section of the tunnels, the distance between parallel cracks or detect open joints with pinpoint precision.

Scientists from Universidad Carlos III of Madrid (UC3M) are participating in ROBINSPECT, a European research project that is developing an intelligent robotic system for the automated inspection of highway and railroad tunnels.

(Photo Credit: UC3M)

Source: Carlos III University of Madrid