Memory devices based on magnetism are one of the core technologies of the computing industry, and engineers are working to develop new forms of magnetic memory that are faster, smaller, and more energy efficient than today's flash and SDRAM memory. They now have a new tool developed by a team from the National Institute of Standards and Technology (NIST), the University of Maryland Nanocenter and the Royal Institute of Technology in Sweden—a method to detect defects in magnetic structures as small as a tenth of a micrometer even if the region in question is buried inside a multilayer electronic device.*

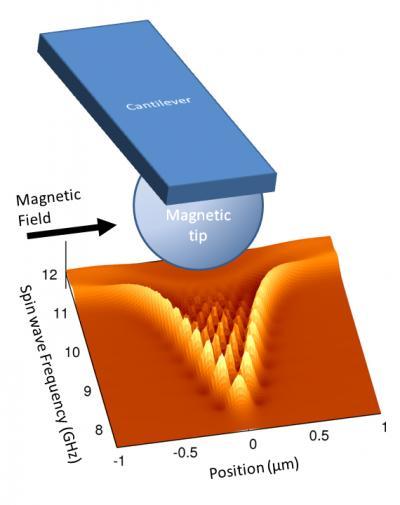

The technique demonstrated at the NIST Center for Nanoscale Technology (CNST) builds on work by researchers at the Ohio State University.** The idea is to trap and image oscillating perturbations of a magnetic field—"spin waves"—in a thin film. Trapped spin waves provide scientists with a powerful new tool to nondestructively measure the properties of magnetic materials and search for nanoscale defects that could or have caused memory failures, especially in multilayer magnetic systems like a typical hard drive, where defects could be buried beneath the surface.

According to NIST researcher Robert McMichael, when left alone, the material's magnetization is like the surface of a pond on a windless day. The pond is comprised of smaller magnetic moments that come with the quantum mechanical "spin" of electrons. Tap the surface of the pond with a piece of driftwood, or microwaves in this case, and the surface will begin to ripple with spin waves as the microwave energy jostles the spins, which, in turn, jostle their neighbors.

Trapped beneath the magnetic tip of a microscale cantilever, spin waves can be used to non-destructively measure the properties of magnetic materials and search for nanoscale defects, especially in multilayer magnetic systems like a typical hard drive, where defects could be buried beneath the surface.

(Photo Credit: McMichael/NIST)

"The trick we play is to tune the microwaves to a frequency just outside the band where the spin waves can propagate—except right under our magnetic probe tip," says McMichael. "It's like the pond is frozen except for a little melted spot that we can move around to check magnetic properties at different spots in the sample."

The trapped spin waves are disturbed by defects in the material, and this effect allows the defects to be characterized on 100 nm length scales.

Previous work had shown this same effect in magnetic spins that were oriented perpendicular to the magnetic film surface, meaning that the individual spins coupled strongly with their neighbors, which limited the resolution. This new work adds the extra feature that the magnetic spins are aligned in plane with one another and are not as tightly coupled. This setup is not only more representative of how many magnetic devices would be structured, but also allows for tighter focusing and better resolution.

Source: National Institute of Standards and Technology (NIST)