– Our idea was to find a way to adapt these natural processes to nanofabrication. This led us to an incidental finding that a focused ion beam can locally induce bending with nanoscale resolution.

The technology has various applications in the fabrication of nanoscale devices. The structures are surprisingly resilient:¬ the team found them to be quite sturdy and robust under a variety of adverse conditions, such as electrostatic discharge and heating.

– Because the structures are so small, the coupling and the magnitude of typical nanoscale forces acting on them would be commensurately small, reminds Docent Sorin Paraoanu, the leader of the Kvantti research group, Aalto University.

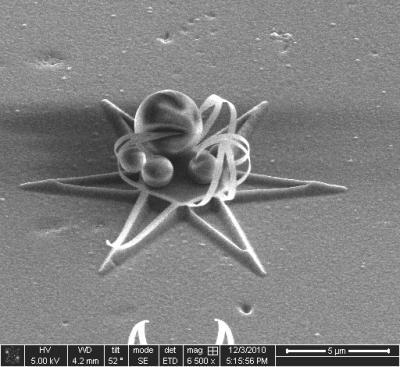

– As for applications, we have demonstrated so far that these structures can capture and retain particles with dimensions of the order of a micrometer. However, we believe that we are just scratching the tip of the iceberg: a comprehensive theory of ion-assisted self-assembly processes is yet to be reached, notes Paraoanu.

The video shows the assembly of a metallic three-dimensional cage, as the nanopatterned film is bent along precisely defined folding lines due to the compressive stress induced by an ion beam. The technology demonstrated by this team of researchers could be used in the future to create extremely complex devices with nanoscale dimensions.

(Photo Credit: Juha Juvonen and Mikko Raskinen, Aalto University)

Micro-particles of lactose are traped in self-organized structures made from the thin film metal. The scale bar represents 4 micrometers.

(Photo Credit: Khattiya Chalapat)

Source: Aalto University