"Janus capsules differ from Janus spheres: the former are hollow structures, and their partially permeable shell is made of colloidal particles. How to make such a 'two-faced bubble' using micro- and nanoparticles? Many researchers reflect on the problem. We proposed a really not complicated solution", says Dr Zbigniew Rozynek (IPC PAS), who experimentally studied Janus capsules during his postdoctoral training at Norwegian University of Science and Technology in Trondheim.

In their experiments, an international team of researchers produced Janus capsules with drops of single millilitres in volume. The drops were coated, for instance, with polystyrene or glass nanoparticles with diameters of about 500 nm (billionth parts of a meter) or 1000 nm, respectively. Also differently coloured polyethylene particles were used.

The experiments were performed with oil drops suspended in another oil. To a so prepared environment micro- or nanoparticles of one type were placed and deposited on the surface of a selected drop. Then, particles of another type were brought to the surface of the second drop. Due to the action of capillary forces, the particles were durably kept on the surfaces of both drops, being approximately uniformly distributed.

When an external electric field was turned on, microflows were induced inside and outside the drops. The microflows transported the particles toward the electric 'equator'. In this step, the packing of colloidal particles could be controlled by shaking the drops in a slowly alternating electric field. The way how the particles are packed is an important factor, as it determines the number and size of pores of the future capsule, and consequently the capsule permeability.

The microflows around the electric equators of the drops resulted in formation of a ring-shaped ribbon, composed of densely packed particles , whereas both electric 'poles' became particles-free regions. At the same time, the poles of each drop were acquiring opposite electric charges.

Two oil drops, covered with particles of different properties, coalesce due to the action of an alternating electric field, forming a Janus capsule.

(Photo Credit: IPC PAS, NTNU)

Opposite electric charges attract one another, so the drops with charged poles were heading to each other. In this step, the only thing to do was to convince both drops not only to adjoin with their poles, but actually to merge. For that purpose the long-known electrocoalescence was used: the drops were stimulated for faster merging by an electric field. Finally the drops electrocoalesced, resulting in the formation of a Janus capsule. Due to a dense packing of particles within the capsule the particles of different types virtually did not mix with each other.

"It's like the famous James Bond's martini: it was always to be shaken, not stirred", laughs Dr Rozynek.

The ultimate capsule appearance was determined by the number of particles deposited on the surfaces of initial drops. If the particles covered both drops with a uniform film, extending almost to the poles, the coalescence resulted in a non-spherical structure. When empty areas around the poles were suitably larger, the Janus capsules acquired a spherical shape. Finally, if the ribbons around the equators of the initial drops were narrow, the coalescence resulted in formation of a structure, which could be called a Janus ring.

The rings with two parts composed of two different types of particles provide interesting opportunities. They can be further stuck each other and produce more complex striped structures. The capsules could be then composed of alternately placed strips of particles, with each strip having different properties than its neighbours.

Janus capsules enable encapsulation of microobjects, nanoparticles or molecules, which must be protected against the environment because of their sensitivity or reactivity. Different properties of both capsule parts make it easier to control the movement of the capsules and the release of their contents. In view of these factors, Janus capsules may find numerous applications. The proposed method for producing the Janus capsules is potentially of great importance for pharmaceutical, dye or food industries, as well as for the development of materials engineering and medicine.

These are typical capsules (mainly Janus capsules) obtained with the method described in the press release of the Institute of Physical Chemistry of the Polish Academy of Sciences in Warsaw.

(Photo Credit: adopted from Nat. Commun. 5, 3945 (2014))

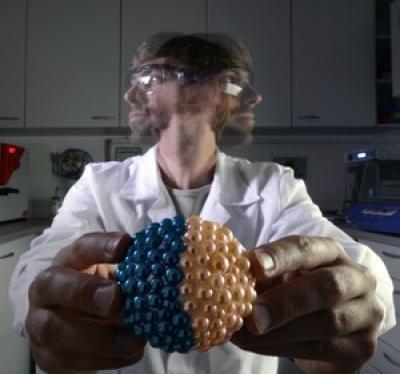

Dr Zbigniew Rozynek from the Institute of Physical Chemistry of the Polish Academy of Sciences in Warsaw presents a model of Janus capsule.

(Photo Credit: IPC PAS, G. Krzyzewski)

Source: Institute of Physical Chemistry of the Polish Academy of Sciences