Rapid economic growth and urbanization in developing countries are accompanied by serious particulate air pollution, i.e. haze. The haze has raised worldwide concerns regarding its impacts on visibility, human health and climate etc. Intense efforts have been paid recently to study the chemical and physical properties of haze particles. However, little effort has been done to explore the mechanical properties of haze particles due to their tiny size.

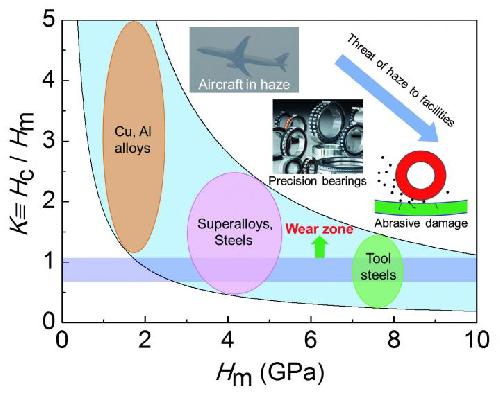

By tackling a series of difficulties in collecting representative samples and employing a cutting-edge in situ micromechanical testing system, Prof. Zhiwei Shan's research team from Xi'an Jiaotong University for the first time, quantitatively investigated the mechanical properties of individual haze particles. The authors demonstrated that the compressive strength of a significant fraction of haze particles is high enough to generate abrasive damage on frequently used industrial alloys. This means that once these particles get into the gaps of the precision parts, such as gear or piston, they will be able to generate abrasive damage and therefore reduce their service life.

"Considering the heavy air pollutions currently running rampant in developing countries, our findings suggest that appropriate preventive measures should be taken immediately to guard against the potential damage from haze, such as to assemble the precision parts in clean room, to seal the gap between sliding parts and to add special filter for air 'breathing' engines", said Prof. Zhiwei Shan.

Critical criterion for haze particles to generate abrasive damage to alloys. Credit: ©Science China Press

Critical criterion for haze particles to generate abrasive damage to alloys. Credit: ©Science China Press

source: Science China Press