Researchers from North Carolina State University have developed a technique for controlling the surface tension of liquid metals by applying very low voltages, opening the door to a new generation of reconfigurable electronic circuits, antennas and other technologies. The technique hinges on the fact that the oxide "skin" of the metal – which can be deposited or removed – acts as a surfactant, lowering the surface tension between the metal and the surrounding fluid.

The researchers used a liquid metal alloy of gallium and indium. In base, the bare alloy has a remarkably high surface tension of about 500 millinewtons (mN)/meter, which causes the metal to bead up into a spherical blob.

"But we discovered that applying a small, positive charge – less than 1 volt – causes an electrochemical reaction that creates an oxide layer on the surface of the metal, dramatically lowering the surface tension from 500 mN/meter to around 2 mN/meter," says Dr. Michael Dickey, an associate professor of chemical and biomolecular engineering at NC State and senior author of a paper describing the work. "This change allows the liquid metal to spread out like a pancake, due to gravity."

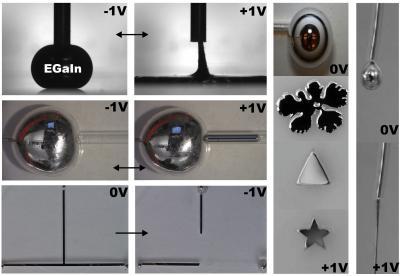

Liquid metals normally form a spherical shape due to their large surface tension. By applying a small voltage to the metal in water, a surface oxide forms on the surface of the metal and lowers the surface tension. Reversing the bias can remove the oxide and return the metal to a large surface tension. These phenomena can be utilized to control the shape of the metal and get it to flow in and out of capillaries.

(Photo Credit: Mohammad Khan)

The researchers also showed that the change in surface tension is reversible. If researchers flip the polarity of the charge from positive to negative, the oxide is eliminated and high surface tension is restored. The surface tension can be tuned between these two extremes by varying the voltage in small steps. Video of the technique in action can be seen here.

"The resulting changes in surface tension are among the largest ever reported, which is remarkable considering it can be manipulated by less than one volt," Dickey says. "We can use this technique to control the movement of liquid metals, allowing us to change the shape of antennas and complete or break circuits. It could also be used in microfluidic channels, MEMS, or photonic and optical devices. Many materials form surface oxides, so the work could extend beyond the liquid metals studied here."

Dickey's lab had previously demonstrated a technique for "3-D printing" liquid metals, which used the oxide layer formed in air to help the liquid metal retain its shape – the exact opposite of what the oxide layer does to the alloy in a basic solution.

"We think the oxide's mechanical properties are different in a basic environment than they are in ambient air," Dickey says.

Source: North Carolina State University