Boston, MA – A team of bioengineers at Brigham and Women's Hospital (BWH) is the first to report creating artificial heart tissue that closely mimics the functions of natural heart tissue through the use of human-based materials. Their work will advance how clinicians treat the damaging effects caused by heart disease, the leading cause of death in the United States.

"Scientists and clinicians alike are eager for new approaches to creating artificial heart tissues that resemble the native tissues as much as possible, in terms of physical properties and function," said Nasim Annabi, PhD, BWH Renal Division, first study author. "Current biomaterials used to repair hearts after a heart attack and other cardiovascular events lack suitable functionality and strength. We are introducing an alternative that has the mechanical properties and functions of native heart tissue."

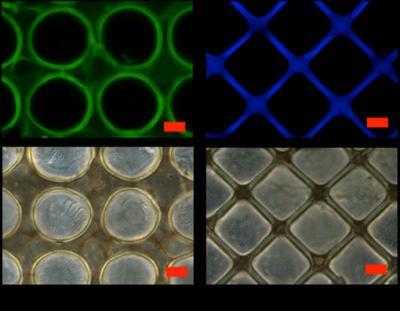

Various microfabrication techniques were used to make highly elastic hydrogels with well-defined micropatterns.

(Photo Credit: Image courtesy of Ali Khademhosseini lab.)

The study was published online on April 26, 2013 in Advanced Functional Materials.

The researchers created MeTro gel—an advanced rubber-like material made from tropoelastin, the protein in human tissues that makes them elastic. The gel was then combined with microfabrication techniques to generate gels containing well-defined micropatterns for high elasticity.

The researchers then used these highly elastic micropatterned gels to create heart tissue that contained beating heart muscle cells.

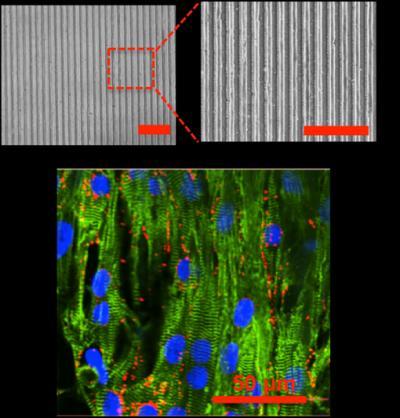

"The micropatterned gel provides elastic mechanical support of natural heart muscle tissue as demonstrated by its ability to promote attachment, spreading, alignment, function and communication of heart muscle cells," said Annabi.

The researchers state that MeTro gel will provide a model for future studies on how heart cells behave. Moreover, the work lays the foundation for creating more elaborate 3D versions of heart tissue that will contain vascular networks.

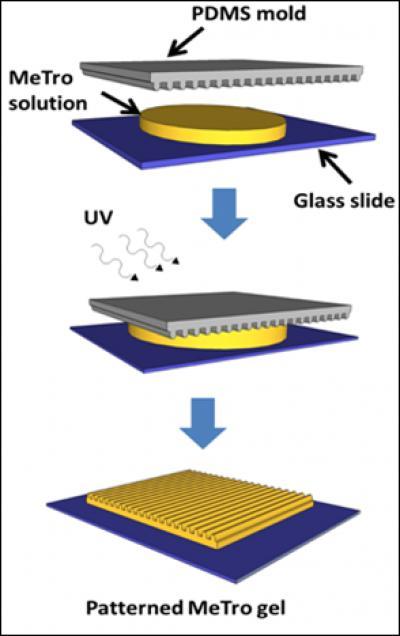

Researchers made a micropatterned MeTro gel by placing the MeTro solution on a glass slide, and then using a mold and UV light to impress a micropattern on it.

(Photo Credit: Image courtesy of Ali Khademhosseini lab.)

"This can be achieved by assembling tandem layers of micropatterned MeTro gels seeded with heart muscles cells in different layers," said Ali Khademhosseini, PhD, BWH Division of Biomedical Engineering, co-senior study author. "As we continue to move forward with finding better ways to mend a broken heart, we hope the biomaterials we engineer will allow us to successfully address the limitations of current artificial tissues."

These images show heart muscle cells aligning and stretching on the surface of micropatterned gels.

(Photo Credit: Image courtesy of Ali Khademhosseini lab.)

Source: Brigham and Women's Hospital